Integrating electronic exhaust cutouts (EECs) requires careful consideration of vehicle dynamics and compatibility with other parts for optimal performance and longevity. Proper setup ensures improved engine efficiency, reduced backpressure, and increased power output while maintaining smooth driving experience through precise alignment, sealing, cleaning, and regular inspections. Choosing appropriate brake pads and considering interactions with cold air intakes (CAIs) are crucial to prevent wear and maintain peak vehicle performance.

In today’s automotive landscape, integrating electronic exhaust cutouts (EECs) and headers is a popular upgrade for performance enthusiasts. This article provides an insightful guide on achieving seamless compatibility between these components. We’ll delve into the fundamentals of EECs and headers, explore critical factors ensuring flawless integration, and offer best practices for installation and maintenance. Optimize your vehicle’s exhaust system with these essential tips for top-notch performance and efficiency.

- Understanding Electronic Exhaust Cutouts and Headers

- Key Factors for Ensuring Seamless Compatibility

- Best Practices for Installation and Maintenance

Understanding Electronic Exhaust Cutouts and Headers

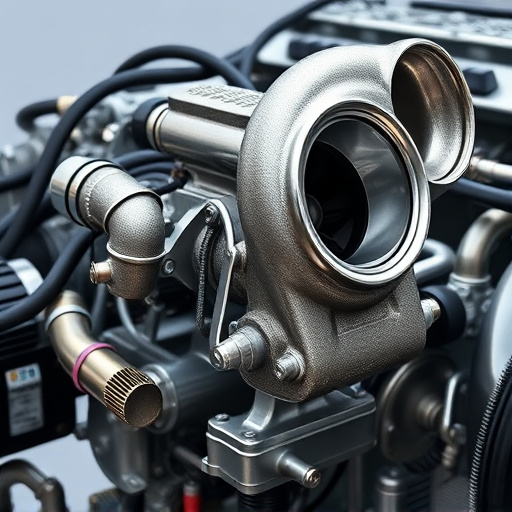

Electronic exhaust cutouts and headers are advanced components designed to enhance vehicle performance and optimize exhaust systems. These cutting-edge systems replace traditional exhaust tips and mufflers, offering a range of benefits. By carefully controlling airflow and gas flow, they can improve engine efficiency and reduce backpressure, resulting in increased power output and better torque delivery. This technology is particularly popular among car enthusiasts seeking to unlock their vehicles’ full potential.

Integrating electronic exhaust cutouts requires consideration of various factors, especially when it comes to compatibility with other suspension components. When installing these systems, ensuring proper alignment and fitment is crucial. The advanced electronics in these cutouts must be compatible with the vehicle’s computer system to ensure seamless operation and avoid any potential issues with sensors or control modules. Proper setup ensures not only optimal performance but also a smooth driving experience.

Key Factors for Ensuring Seamless Compatibility

When ensuring seamless compatibility between electronic exhaust cutouts (EECs) and headers, several key factors come into play. First and foremost, it’s essential to verify that the EECs are designed specifically for your vehicle model and engine type. Compatibility issues often arise from universal or generic EECs that don’t account for unique vehicle dynamics, leading to potential performance hiccups.

Additionally, considering the interplay between EECs and high-performance parts like cold air intakes (CAIs) is crucial. Improper integration can disrupt airflow patterns, negating the benefits of both components. Equally important is matching the EECs with compatible brake pads, as certain combinations may cause unnecessary wear or affect braking performance. Careful selection based on vehicle specifications and intended use ensures optimal functionality and longevity for these advanced automotive systems.

Best Practices for Installation and Maintenance

When it comes to installing and maintaining electronic exhaust cutouts (EECs), following best practices ensures optimal vehicle performance and longevity. Begin by ensuring proper alignment and sealing during installation, as any misalignment can lead to leaks and reduced performance. Use high-quality gaskets and seals recommended by the manufacturer to maintain a tight connection between the EEC and the header or muffler system. Regular cleaning and inspection are crucial; remove any buildup of carbon deposits or debris that could restrict airflow, which is essential for maintaining peak vehicle performance.

Moreover, keep brake components and suspension kits in excellent condition alongside your EECs. Regularly inspect these systems for wear and tear, replacing parts as necessary to maintain safety standards. Proper maintenance not only enhances vehicle performance but also ensures the longevity of your exhaust system, contributing to a smoother driving experience over time.

When integrating electronic exhaust cutouts into your vehicle, considering compatibility is key. By understanding the fundamentals of these components and implementing best practices during installation and maintenance, you can ensure a seamless fit and optimal performance. Keep in mind the crucial factors for compatibility, such as material choices and design specifications, to avoid any issues. With proper care, electronic exhaust cutouts offer a modern solution for improved vehicle efficiency and enhanced driving experience.